Understanding the Problem: Dirt, Grime, and Solar Panel Efficiency

For island power grids, remote off-grid sites, and far-away power plants, solar photovoltaic containers are a convenient, one-stop renewable energy solution. But the catch is: grime. Moroccan desert dust, sea salt spray in coastal Indonesian beaches, or Nigerian city pollution leftovers—solar panels in containers see their efficiency dwindle quickly due to the buildup of grime. And with labor being too expensive or logistically impossible, what's the answer?

That is where the Solar Photovoltaic Container self-cleaning solution steps in—a new trend in solar maintenance technology that maintains panels clean and operating at top levels, without ongoing human intervention.

What is a Solar Photovoltaic Container Self-Cleaning Solution?

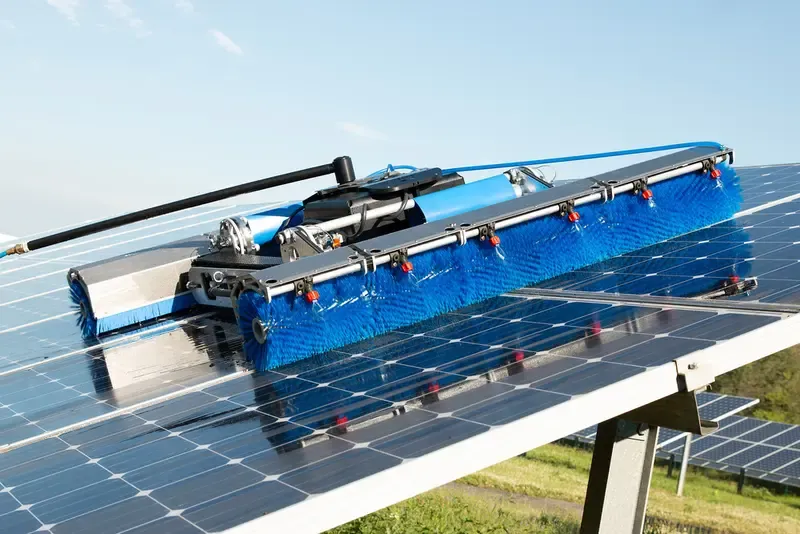

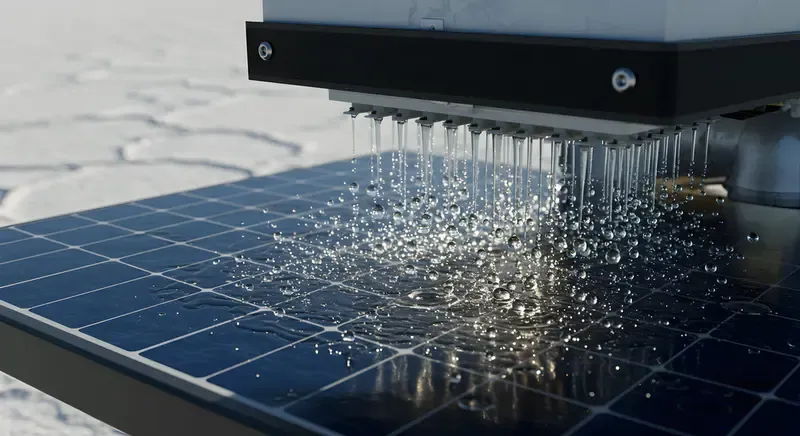

Essentially, it's a computerized cleaning system that is designed for containerized solar panels. They have waterless or low-water robot arms, sensor-enabled sweepers, or even AI-enabled modules that monitor dust buildup and roll out cleaning routines accordingly.

Some higher-end models are integrated into the container itself that can even be cleaned inside while being transported or in extreme weather conditions. That is particularly important for high-dust or high-humidity areas where solar power loss may be more than 20–30% if left uncleaned, according to a 2022 SolarPower Europe report.

Real-World Case Study: Spain’s Murcia Region Solar Trials

In 2023, a trial experiment was conducted in Murcia, Spain, on a 500kW container solar system with an automatic dry-cleaning robot produced by SolarCleano. In 6 months of total lack of rainfall, the system had over 95% efficiency of performance, while a nearby similarly-sized manually-cleaned facility was only reaching 72%.

The takeaway? An effective self-cleaning installation not only cuts labor costs, but even improves return on investment by preserving output in the long run.

Who Needs It Most? Deployment Options

Consider this: if you have your solar installation on an island, far from regular maintenance crews, how many times can you pay someone to send someone just to clean off panels?

The answer is: you probably can't. This is why self-cleaning technology is most beneficial in container-based solar units put in areas like the Maldives, Philippines, or Pacific island nations. There might be no maintenance facilities in these areas, but they require continuous energy supply—especially for hospitals, water purifiers, and communication hubs.

Most Crucial Specs to Investigate When Choosing a Self-Cleaning System

When choosing a cleaning system, the following are some of the most important specifications to investigate:

- IP65 or higher rating:For dusty and wet conditions.

- AI sensors or programmable logic controllers (PLC):Enables condition-based cleaning, eliminating unwanted energy expenditure.

- Waterless cleaning mechanisms:Appropriate for drought areas or isolated deserts.

- Low power consumption from the container system itself:So that it doesn't compromise generation capacity.

And here's something to think about: Does it make sense to spend a lot of money on an automated cleaner if your panels are only making 100W a day in a cloudy microclimate? In that case, probably not. But in high-output sunny areas, self-cleaning is an energy multiplier.

Industry Trends: AI and Modular Integration

Fresh cleaning systems are moving beyond the basic timer-controlled configurations. Companies like Ecoppia and SunBrush now have AI-driven dirt detection, with robotic arms being mounted during retrofitting in a modular fashion. These technologies are part of the general industry push for intelligent solar—where efficiency is not just about creating power but also looking after it.

Environmental Impact: Sustainability Beyond Solar

Interestingly, some of the solutions nowadays focus on eco-friendliness as well as functionality. For example, a pilot in Rajasthan, India, used a self-cleaning setup with recycled graywater from a nearby desalination plant. The result? Sterilized panels and a low environmental impact. This kind of holistic design is now a top differentiator in spaces that are concerned about water usage.

Cost Implications and ROI

Though costs are automation level sensitive, a 100kW container's mid-sized self-cleaning system can range from $2,000–$5,000 as a once-off cost. Within 5 years, however, studies demonstrate a potential 20% increase in total energy output—which translates into faster payback period, especially in regions where downtime is unacceptable.

Rather than applying cleaning as an afterthought, newer Solar Photovoltaic Container models are now including self-cleaning directly in their design from the factory floor. It is revolutionizing container-based solar into a plug-and-play utility for low-maintenance off-grid energy deployment.

It raises a basic question: Shouldn't self-cleaning come as a standard option on all container-based solar solutions and not as an option for upgrade? From the data, the answer is ever more loudly yes.