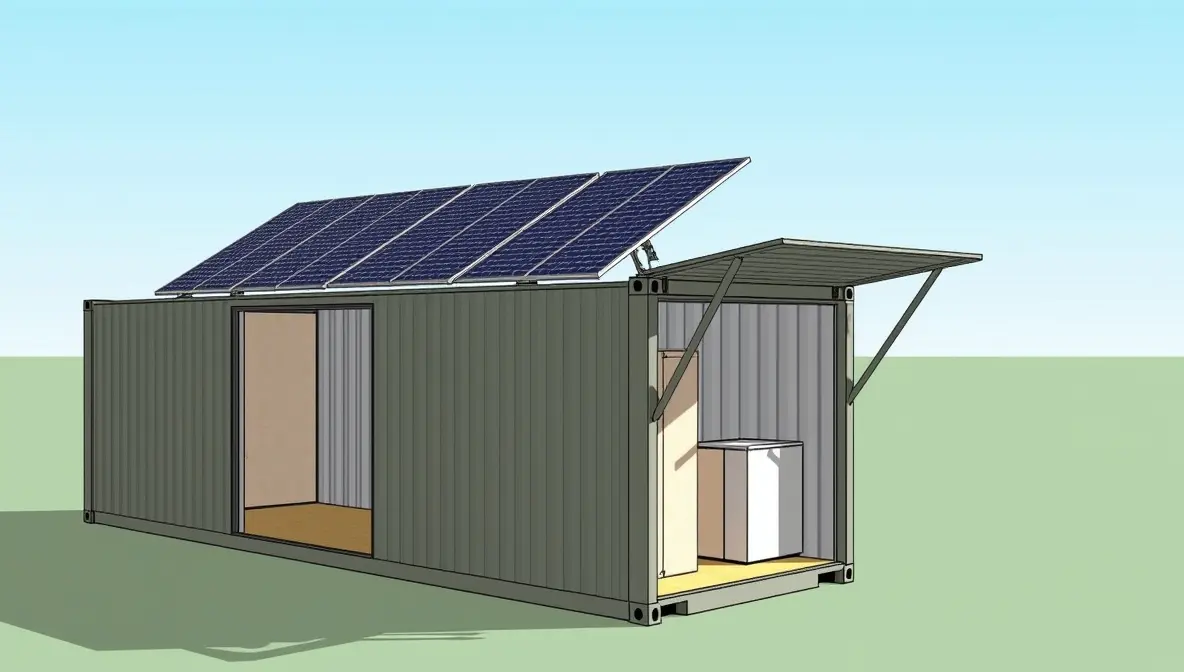

This paper is a guide to mobile foldable photovoltaic containers installation and operation information and features, walking renewable energy project managers, emergency first responders, and off-grid technicians through each step they should be aware of. We document audience needs and support web content, record best practices from site preparation to commissioning, and communicate safety measures - from structural anchoring to electrical grounding. Practical field information, technical vocabulary, and high-resolution images of sophisticated solutions such as the LZY-MSC3 Bolt-On Mobile Solar Container provide expert and informative guidance.

Audience and material analysis

Solar foldable mobile boxes have a number of applications – off-grid research stations, disaster relief, out-of-door expeditions and off-grid industrial operations. Major target audience segments are:

- Project managers and engineers: need detailed technical data, guidelines for installation and legislation.

- Emergency coordinators: need knowledge of speedy deployment procedures and inventory details accessibility.

- Off-grid hobbyists and small businesses: seek low-cost assembly ideas and service tips.

Examples of websites featuring this topic range from promotional messages (e.g. Huijue Group's Canton Fair promotion) to EPC businesses (BoxPower) and off-the-shelf PV system hardware (Tycorun).

Installation Planning and Site Preparation

1. Evaluate container sizes

Typical 20-foot ISO "dry" container size is 6.06 m × 2.44 m × 2.59 m, with corner castings anchorage and stacking rating according to ISO 668. Slightly taller arrangements (9 ft 6 in tall) will create more clearance but need to be securely anchored.

2. Select deployment location

- Terrain and load capacity: Provide ground load capacity for gross container weight (~24 000 kg) and wind loads, and deploy panels.

- Sun exposure: Place container with optimal south exposure (northern hemisphere) for highest array output.

- Access and logistics:Provide crane or forklift access for off-loading and unit positioning.

3. Foundation and leveling

- Concrete pads or screw anchors:Install reinforced foundations or soil anchors at corners, depending on soil conditions.

- Level container: Utilize hydraulic jacks and precise levels to achieve ±1° or better tilt to minimize panel misalignment losses.

Mechanical Installation Steps and Safety Precautions

1. Unloading and Positioning

- Crane Rigging:Use qualified slings with a capacity exceeding the container tare weight; provide a minimum safety factor of 2:1 per OSHA rigging practices.

- Observers and Communications:Use trained operators and proper radio or hand signal procedures.

2. Structural Anchorage

- Twist Locks and Corner Castings:Install ISO twist locks or bolt base plates onto foundation anchor bolts.

- Wind Load Support:Cross supports or guy wires to resist gusts, especially for deployed foldable panels.

3. Deployment of Foldable Array

- Pre-Inspected Hinges and Tracks:Visually inspect telescopic rails, reducers, and struts for damage or obstruction.

- Clearance Check:1 m clearance from panels to avoid pinch points.

- Lockout Tagout (LOTO): Lock out mechanical actuators for manual adjustments per OSHA LOTO requirements.

Electrical Installation: Wiring, Grounding, and Safety

1. PV String Wiring

- Wire Sizing and Protection: Install sunlight-resistant, UV-resistant wire per NEC 690.8 sizes to limit voltage drop to less than 3%.

- Conduit and Junction Boxes: Use weatherproof (IP65) junction boxes around the combiner box array.

2. Grounding and Bonding

- Equipment Grounding Conductor (EGC):Bond module frames, racks, and metal enclosures to the grounding electrode system.

- Surge Protection Device (SPD): Suppress transient overvoltages with a Type 2 SPD on the inverter and Omron varistors near the array.

3. Inverter and Control System

- Mount Inverter Indoor or Indoor:In a well-ventilated, air-conditioned area inside the container.

- EMS Integration:Mount the LZY-MSC3 Bolt-On Mobile Solar Container's EMS to enable remote monitoring and field diagnostics to reduce "mean time to repair."

Operational Precautions and Maintenance

1. Daily Checks

- Visual Inspection:Look for loose wire, rust, or panel grime that generates hotspots.

- EMS Warning:Respond immediately to EMS-initiated warnings, e.g., earth fault or arc-fault warning alarms.

2. Seasonal Controllers

- Panel Orientation Optimization:Optimize tilt angles manually seasonally (±15°) in case tracking is not automated.

3. Safety Devices and Protocols

- Personal Protective Attire (PPE):Wear rubber-insulated gloves, dielectric boots, and arc-flash-approved clothing while handling electricity.

- Fall Protection:Roof panel entry into a container should be safeguarded by guardrail systems or personal fall arrest devices according to OSHA 29 CFR 1926.502 regulations.

Case Studies and Data Insights

- Drill Deployment:Huijue Group successfully tested a 120 × 480 W panels and exported all mechanical devices in a 20 ft container and had the complete set deployed in 25 minutes with six workers.

- Energy Gain Output:Foldable sun-tracking type array of LZY-MSC2 models built +25% back-return instances for desert test cases than fixed mounting.

- Reliability Performance Measures:BoxPower achieves <1% system outage for 50+ container-scale microgrids for two years of proactive EMS tuning.

Industry Terminology and Industry Trends

- Protection IP65:Dustproof and water-jet-proof enclosures to operate with hostile environments.

- BMS (Battery Management System):Aims at lithium-ion storage for state-of-charge balancing and prevention of thermal runaway.

- EMS (Energy Management System):Provides SCADA-grade control, remote firmware updates, and fault analysis down to unit faults.

Future trends include AI-based performance forecasting, composite rack technology for weight reduction, and blockchain-secured energy transfer between the container units.

Actionable Installation and Operation Checklist

1. Site & Container Prep:

- Check ISO container size and ratings.

- Level and set anchor container on soil test.

2. Mechanical Installation:

- Offload with professional rigging.

- Wind twist-locks and bracing in position.

3. Electrical Connection:

- DC cables run in UV-resistant conduit.

- Ground frames and install SPDs.

4. Commissioning

- Perform PV module I–V curve tests and inverter start-up per manufacturer specifications.

- Inspect EMS connectivity and alert thresholds.

5. Routine Maintenance:

- Routine visual inspection and EMS log check.

- Semi-periodic tilt adjustment and cleaning.

By strict compliance with such Notes in mobile solar container installation, strict adherence to industry best practice installation procedures for solar power boxes, and use of products with heavy-duty functionality like the LZY-MSC3 Bolt-On Mobile Solar Container, operators ensure safe, efficient, and 20ft Container Solar Energy Innovation-improved power delivery wherever deployment is required.